Certified Construction Quality Manager (CCQM)

The Certified Construction Quality Manager (CCQM) is a skilled professional dedicated to upholding high-quality standards across every phase of a construction project. This role involves overseeing contract creation, strategic planning for quality assurance, resource allocation, design review, documentation requirements, and project closure. CCQMs implement quality control measures, foster team collaboration, apply project management best practices, and address risk, environmental, and safety factors to elevate project quality and meet expected outcomes. Additionally, they use statistical analysis and quality improvement tools to refine construction processes, ensuring final deliverables align with stakeholder expectations and industry standards.

Exam Requirements

- 8 Years: Candidates must have at least eight years of practical experience in one or more areas covered by the Construction Quality Manager Certification Body of Knowledge.

- 3 Years: At least three of these years must be in a “decision-making” role.

- A “decision-making” role involves authority over defining, executing, or managing projects/processes and being accountable for outcomes. This may include, but is not limited to, supervisory or managerial roles.

Candidates should have held full-time, paid positions. Up to one year of experience may come from internships or apprenticeships.

Education Requirements

Candidates with formal education from a college, university, or technical school may be eligible for a reduction in the eight-year experience requirement, as follows (only one reduction can be applied):

- Technical or trade school diploma — one year reduction

- Associate degree — two years reduction

- Bachelor’s degree — four years reduction

- Master’s or doctoral degree — five years reduction

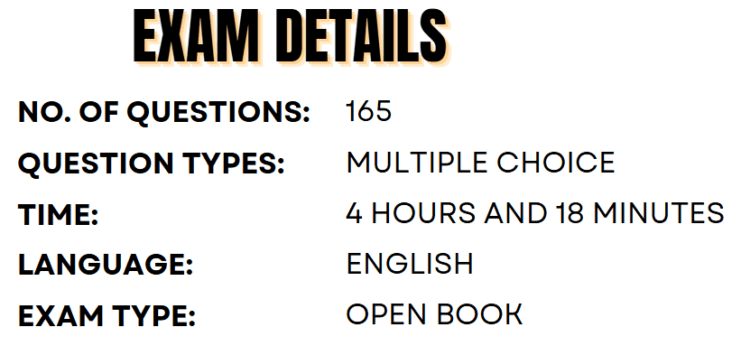

Exam Details

Every certification candidate must successfully complete an exam featuring multiple-choice questions that assess their understanding of the Body of Knowledge. The CCQM Computer-Based Exam is a single-section test with 165 multiple-choice questions available only in English. Of these, 150 questions are scored, while 15 are unscored. The total appointment time is four and a half hours, with an exam duration of 4 hours and 18 minutes. All exams are open book. Candidates are required to bring their own reference materials.

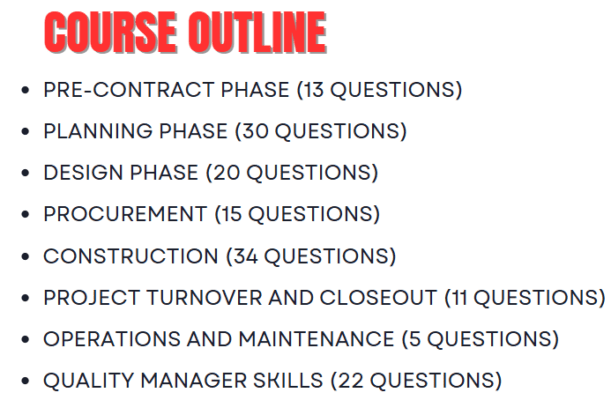

Course Outline (Body of Knowledge)

The Body of Knowledge topics include additional details through subtext explanations and indicate the cognitive level at which exam questions will be designed. This information serves as a guide for candidates preparing for the exam. The topics include:

I. Pre-contract Phase (13 Questions)

A. Project delivery, contract, and payment models

- Project delivery methods

- Identify various types of clients (e.g., private, commercial, federal, state, municipal, and international) and their use of project delivery methods, such as Engineering, Procurement, Construction Management (EPCM), Design-Bid-Build (DBB), Design-Build (DB), Design, Build, Finance, and Maintain (DBFM), Construction Manager at Risk (CMAR), and Construction Manager for Fee (CMFF). Understand project lifecycle phases (e.g., project initiation, project planning, project execution, monitoring & control, and project closeout) align with the project delivery method. (Understand)

- Contract types

- Understand various types and sources of contracts (e.g., Public-Private Partnership (P3), DesignBuild Institute of America (DBIA), American Institute of Architects (AIA), International Federation of Consulting Engineers (FIDIC), lump sum, subcontract, consultant agreement, consultant staffing agreement, joint venture contracts, and purchase orders) along with their quality requirements. Recognize contract terms and conditions (e.g., liquidated damages [LDs], liquidated and ascertained damages [LADs], and general damages [GDs]). (Understand)

- Payment models and methods

- Understand the risks associated with and the differences between payment models (e.g., unit rates and reimbursable costs) and methods (e.g., Guaranteed Maximum Price (GMP). (Understand)

- Payment documentation requirements

- Understand payment documentation requirements, such as schedule of values, percent completion determination (cost complete vs. work complete), retainage, billing methods, and billing terms. (Understand)

B. Contractual requirements

- Scope, schedule, and resource planning

- Define a project’s scope components (e.g., boundaries), develop the schedule and resource plan, track milestones, and identify roles and responsibilities in terms of quality of different entities (e.g., trade partner, contractor, owner, and quality manager). (Analyze)

- Quality management inputs

- Determine and analyze quality management inputs (e.g., Certificate of Authorization (CoA), input for proposals, and Request for Proposal (RFP)) to adhere to a project’s quality standards. (Analyze)

- Stakeholders

- Identify and acknowledge internal and external stakeholders and engage them. (Apply)

- Local contract opportunities and contract values

- Understand the impact of local contract (e.g., DBE, SWaM, local small businesses and suppliers) opportunities and contract values (e.g., allocation percentages to local resources) in relation to the quality of a project. (Understand)

- Procurement and contracting methods

- Understand procurement methods, such as sole source, single source, competitive bid, lowest bid, technical bid, and contracting methods, such as general contracting, and subcontracting. Identify and understand the best value proposal. (Understand)

- Delegated design

- Apply delegated design or specialized engineering to transfer specific design responsibilities for a project to a contractor or subcontractor and understand the associated risks. (Apply)

C. Bid evaluation and finalization

- Prequalification process

- Analyze the role of audits in the prequalification process, align the prequalification process to meet organizational needs, and explain the prequalification process for short-listed bidders. (Analyze)

- Criteria development

- Review the criteria for assessing and comparing bids (e.g., dollars, schedule, lead times, workforce, products, assemblies, safety, sustainability) to integrate the bid criteria with quality requirements, critical to quality (CTQ) concepts, and examine bid criteria for the specific contract type in use. (Analyze)

- Bidding process

- Distinguish the role of quality requirements in the context of different contract types during the bidding process. Identify strategies and techniques for building consensus when finalizing quality requirements. (Analyze)

II. Planning Phase (30 Questions)

A. Strategic quality planning

- Project quality strategy development

- Formulate a comprehensive project quality strategy, integrating stakeholder requirements (stated

and implied), procurement requirements, contracting approaches, and regulatory compliance

based on Authority Having Jurisdiction (AHJ), and securing management commitment. Establish

key performance indicators (KPIs) to align with each element of the quality strategy. (Create)

- Formulate a comprehensive project quality strategy, integrating stakeholder requirements (stated

- Environmental, social, and governance (ESG) practices

- Apply sustainable practices and programs (e.g., LEED, ENERGY STAR, and Cradle to Cradle

Certification), social responsibility, and governance standards to enhance the overall quality and

long-term viability of projects. (Apply)

- Apply sustainable practices and programs (e.g., LEED, ENERGY STAR, and Cradle to Cradle

- Alignment of quality plan with other project plans

- Create the quality plan, ensuring alignment with the quality strategy and technology strategy. Align the quality plan with other project plans, such as the Health, Safety, and Environment (HSE) Plan, Execution Plan, Communication Plan, project schedule, and Risk Management Plan. (Create)

B. Quality management systems (QMS)

- Industry standards

- Analyze the quality management system (QMS) to ensure it follows industry standards and understand how it complies with international standards (e.g., ISO 9001, ISO 10006, ISO 14001, and ISO 45001) to deliver quality outcomes. (Analyze)

- Quality Management Plan

- Create a project-specific quality management plan (QMP) that complies with the appropriate QMS, incorporating policies and procedures (e.g., nonconformance control procedures, inspection and testing procedures, and method statements). Integrate PMBOK Guide principles and system assurance practices into the development of the QMS and QMP. (Create)

- Quality assurance (QA)

- Develop and implement quality assurance (QA) practices to verify the project meets quality specifications and is compliant with applicable standards by establishing standardized quality policies and procedures. (Create)

- Quality control (QC)

- Develop and implement quality control (QC) measures such as an inspection and test plan to ensure compliance with requirements. (Create)

C. Resource planning and analysis

- Resource assessment and mobilization

- Identify the specific quality resources and timely availability needed for a project and develop a mobilization plan including allocation and a gap analysis of current and necessary resources. (Create)

- Roles of quality personnel and internal stakeholders

- Ensure all relevant quality personnel and internal stakeholders understand the quality plan and have the necessary knowledge and skills to carry out their responsibilities. Formulate the roles and expectations of quality personnel, contribute to the personnel qualification process, and ensure all personnel understand their roles and responsibilities. (Create)

- Training needs in quality management

- Identify a project team’s quality-specific training needs to achieve project deliverables, develop a training plan, deploy the training, and evaluate the effectiveness of the training. (Create)

- Third-party inspection and outsourcing

- Identify the need for third-party inspection services as applicable and develop criteria for selecting and integrating outsourced quality services into the project. (Create)

- Measurement systems analysis

- Assess the measurement system and its requirements to verify if equipment accurately and reliably measures specific parameters. Ensure calibration and certification requirements are met and that all equipment, including equipment used by subcontractors, is accurate, precise, and compliant with relevant standards and regulations. (Evaluate)

- Quality management tools and infrastructure

- Identify and assess quality tools (e.g., data analysis tools, statistical process control, dashboards, construction pre-control checklists, and budgets) and quality infrastructure essential for effective quality management. (Evaluate)

D. Quality audits

- Audit types

- Identify the appropriate type of audit (e.g., first-party, second-party, and third-party) for different situations, such as personnel independence from the area being audited. (Apply)

- Quality audit plan

- Create and evaluate a quality audit plan that aligns with strategic objectives, key project controls, prime contractor audits, and compliance checks for areas at risk using specific, measurable, attainable, relevant, and time-bound tactics. (Create)

- Audit performance

- Conduct a quality audit to evaluate the management system’s effectiveness, review adherence to standards, and identify nonconformances through detailed observations. (Evaluate)

III. Design Phase (20 Questions)

A. Design inputs

- Quality objectives

- Examine the quality objectives set by the client, owner, or user from the initial scope agreement

and determine how these objectives align with design inputs. Consider the delivery method and

contract when reviewing design phase / development planning. (Analyze)

- Examine the quality objectives set by the client, owner, or user from the initial scope agreement

- Coordination of functional and nonfunctional requirements

- Explain the coordination between functional (e.g., foundation) and nonfunctional (e.g., finish)

requirements and illustrate their application at various levels, such as system and component.

Relate these requirements to industry standards and demonstrate their relationship to overarching

quality objectives. (Apply)

- Explain the coordination between functional (e.g., foundation) and nonfunctional (e.g., finish)

- Design lessons learned and best practices

- Apply lessons learned from previous projects and industry best practices to design inputs.

Understand the impact of value engineering on design. (Apply)

- Apply lessons learned from previous projects and industry best practices to design inputs.

B. Design process

- Stakeholder involvement

- Determine key stakeholders involved in the design process for each discipline. Collaborate with

the subject matter experts from each discipline responsible for making design decisions. Analyze

the impact of these design decisions on quality. (Analyze)

- Determine key stakeholders involved in the design process for each discipline. Collaborate with

- Application of QMS in design feedback

- Apply QMS procedures and interdisciplinary reviews to address feedback related to quality

requirements in the design process. (Analyze)

- Apply QMS procedures and interdisciplinary reviews to address feedback related to quality

- Functionality and constructability reviews

- Participate in reviews that assess the design’s functionality and constructability. Provide quality

inputs that focus on various aspects, such as complexity, inspectability, testability, reliability,

durability, survivability, interoperability, compatibility, maintainability, and comparative cost of

ownership. (Analyze)

- Participate in reviews that assess the design’s functionality and constructability. Provide quality

C. Design outputs

- Quality objectives review

- Apply verification and validation to design outputs to evaluate whether quality objectives are met.

(Apply)

- Apply verification and validation to design outputs to evaluate whether quality objectives are met.

- Cross-disciplinary design review

- Support the design review process across multiple disciplines to identify and address gaps

in design outputs using a design review checklist. Determine and address conflicts within the

overarching system design, among individual component teams, and in interactions between

component teams. (Analyze)

- Support the design review process across multiple disciplines to identify and address gaps

- Criticality levels and inspection

- Analyze the proposed criticality levels for equipment and material. Identify appropriate inspection

levels and methods (e.g., in-process inspection and third-party design review) based on criticality

and budget considerations. (Analyze)

- Analyze the proposed criticality levels for equipment and material. Identify appropriate inspection

D. Quality controls in design

- Project controls

- Evaluate the effectiveness of project controls, including the timeline, in meeting the quality

expectations of stakeholders, such as the client, owner, or user. (Evaluate)

- Evaluate the effectiveness of project controls, including the timeline, in meeting the quality

- Design review output

- Examine the design review output received at each phase (e.g., 30%, 60%, 90%) to determine

its alignment with the expectations of stakeholders, such as the client, owner, or user. (Analyze)

- Examine the design review output received at each phase (e.g., 30%, 60%, 90%) to determine

- Design changes

- Understand sources of design change communication, including requests for proposals (RFPs),

change order directives, addenda, and requests for information (RFIs). Assess and track the

impact of proposed design changes and determine the effectiveness of incorporating any agreedupon changes into the contract. (Analyze)

- Understand sources of design change communication, including requests for proposals (RFPs),

- Design verification and validation

- Understand design verification and validation and understand how the design output conforms to

the design input through the use of reviews, inspections, and testing. (Understand)

- Understand design verification and validation and understand how the design output conforms to

E. Measurement and monitoring

- Design monitoring

- Examine design effectiveness and progress at various gates (e.g., schematic design (SD), design

development (DD), construction documents (CD)) to align with the quality objectives and schedule.

Address any deviations or issues discovered at each gate. (Analyze)

- Examine design effectiveness and progress at various gates (e.g., schematic design (SD), design

- Peer reviews

- Identify the necessity of peer reviews (e.g., design peer reviews and third-party consultant

reviews), evaluate their input, and incorporate them into the quality documentation process.

(Evaluate)

- Identify the necessity of peer reviews (e.g., design peer reviews and third-party consultant

- Quality documentation

- Collaborate with the design review facilitator to document all quality-related activities, decisions,

and changes, ensuring a comprehensive record for evaluating the design’s adherence to quality

standards. (Evaluate)

- Collaborate with the design review facilitator to document all quality-related activities, decisions,

IV. Procurement (15 Questions)

A. Quality requirements

- Quality requirements for procurement

- Collaborate with engineering teams to design functional and nonfunctional quality requirements

for the procurement of specific products or services. Analyze if these requirements are clearly

defined, complete, correct, compliant, and coordinated. (Analyze)

- Collaborate with engineering teams to design functional and nonfunctional quality requirements

- Trade partner requirement alignment

- Develop a strategy, incorporating methodologies such as first article inspection (FAI) and factory

acceptance testing (FAT), to determine whether the trade partner’s inspection and testing plan

aligns with established quality requirements. Incorporate a rigorous review process for the

inspection and test plans to ensure comprehensive evaluation. Additionally, integrate specific

quality requirements for subcontractors and vendors, focusing on their scope of work, historical

performance, compliance with standards, and the thoroughness of their documentation and

plans. (Create)

- Develop a strategy, incorporating methodologies such as first article inspection (FAI) and factory

B. Resource management

- Pre-activity meetings

- Schedule, implement, and oversee pre-activity meetings (e.g., pre-assembly, pre-inspection,

quality kick-off) to review the project’s requirements with the relevant stakeholders. (Evaluate)

- Schedule, implement, and oversee pre-activity meetings (e.g., pre-assembly, pre-inspection,

- Material control and resource identification

- Incorporate material control, material traceability, and vendor requirements into the project prior

to commencement of work. Evaluate the resources needed for various inspections (e.g., selfinspection and certification, third-party inspection), including those conducted at the source and as mandated by regulations. (Evaluate)

- Incorporate material control, material traceability, and vendor requirements into the project prior

- Resource mobilization and management

- Integrate resource qualification and training, along with warehouse quality and material

management into the resource management process. Assess the need for specific resources

tailored to each inspection type, ensuring that these resources are available and properly

allocated, and aligned with the established inspection and test plan. (Evaluate)

- Integrate resource qualification and training, along with warehouse quality and material

C. Risk management

- Risk identification and analysis

- Analyze various risk identification and assessment tools, including failure mode and effects

analysis (FMEA), fault tree analysis (FTA), and strengths-weaknesses-opportunities-threats (SWOT)

analysis. Examine risks based on quantitative and qualitative data related to potential impact on

the project. (Analyze)

- Analyze various risk identification and assessment tools, including failure mode and effects

- Risk treatment

- Evaluate risk mitigation strategies such as risk transfer, retention, acceptance, avoidance.

(Evaluate)

- Evaluate risk mitigation strategies such as risk transfer, retention, acceptance, avoidance.

- Risk monitoring

- Use risk monitoring tools (e.g., risk-based audit programs) and perform surveillance audits

to regularly evaluate identified risks and monitor key factors (e.g., cost, time, safety, supplier

performance), and the criticality of material and equipment. (Evaluate)

- Use risk monitoring tools (e.g., risk-based audit programs) and perform surveillance audits

D. Quality reporting

- Review and interpretation of quality documents

- Evaluate inspection and test reports, quality records, and manufacturers’ data books to ensure

traceability. Assess conformance with product specifications and quality criteria. (Evaluate)

- Evaluate inspection and test reports, quality records, and manufacturers’ data books to ensure

- Documentation and communication of quality insights

- Evaluate and document key insights from the quality management process to inform future

actions. Communicate quality-related insights and determine the appropriate timing, escalation,

and method to alert stakeholders about significant quality issues. (Evaluate)

- Evaluate and document key insights from the quality management process to inform future

- Vendor performance evaluation

- Analyze vendor performance periodically using quality key performance indicators (KPIs) and use

supplier performance incentives (e.g., awards, more wallet share, premium). (Analyze)

- Analyze vendor performance periodically using quality key performance indicators (KPIs) and use

V. Construction (34 Questions)

A. Quality plan deployment

- Construction plans and specifications

- Assess plans and specifications (e.g., permanent and temporary work) in relation to the project’s

quality plan to meet established quality standards. (Evaluate)

- Assess plans and specifications (e.g., permanent and temporary work) in relation to the project’s

- Required permits

- Understand the importance of securing all essential permits before project commencement. (Understand)

- Construction submittals

- Review various types of construction submittals (e.g., action and deferred/delegated), taking into

consideration the interdependency across trades and the project’s quality plan and standards. (Apply)

- Review various types of construction submittals (e.g., action and deferred/delegated), taking into

- Material evaluation

- Evaluate materials to verify their conformity to project specifications. (Evaluate)

- Requests for information or changes

- Participate in the process to track requests for information (RFIs), field change requests (FCRs),

and design change requests (DCRs) to ensure the project remains on track and that objectives

adapt when necessary. (Apply)

- Participate in the process to track requests for information (RFIs), field change requests (FCRs),

B. Process management

- Risk-based inspection and testing strategy

- Develop a risk-based inspection and testing strategy by identifying risks. Establish priorities

for inspections, including modifications based on changes in project requirements (e.g., scope

modifications), and testing in line with specifications (e.g., concrete testing) and accepted

standards or regulations (e.g., welding certifications). (Create)

- Develop a risk-based inspection and testing strategy by identifying risks. Establish priorities

- Quality management processes

- Identify inspection processes for various stages, including source, initial, intermediate, and

continuous. Prioritize program inspections and tests based on their criticality, respective project

stages, and potential impact on overall project quality, ensuring alignment with the project’s

evolving needs and scope changes. Identify the need for procedures for specialized tasks, such

as welding, heat treatment, coating, and soldering. (Evaluate)

- Identify inspection processes for various stages, including source, initial, intermediate, and

- Quality control and monitoring

- Develop a system to address nonconformances, manage nonconformance reports (NCRs) and

corrective action requests (CARs), and implement corrective and preventive action (CAPA). Design

quality protocols and establish criteria for stop work notices. Establish a robust framework for

maintaining quality records. Design a strategy for conducting site quality audits and create a

mechanism for generating and distributing quality reports. (Create)

- Develop a system to address nonconformances, manage nonconformance reports (NCRs) and

C. Destructive and nondestructive tests

- Determine the appropriate scenarios for using destructive and nondestructive test methods and verify those performing the tests are accredited or certified. (Evaluate)

D. Compliance management

- Laboratory accreditation

- Evaluate laboratory accreditation and conduct periodic reviews or surveillance audits based on

project quality requirements. (Evaluate)

- Evaluate laboratory accreditation and conduct periodic reviews or surveillance audits based on

- Compliance monitoring

- Assess compliance with applicable regulatory requirements, standards, and codes,

and conformance to specifications, procedures, and drawings. Document defects and

nonconformities, and collaborate with technical authorities and engineering disciplines to review,

disposition, and resolve identified nonconformities. (Evaluate)

- Assess compliance with applicable regulatory requirements, standards, and codes,

- Regulatory body or Authority Having Jurisdiction (AHJ)

- Conduct regulatory body or AHJ reviews and audits to assess adherence to established criteria

and maintain proper documentation of reviews and audits. (Analyze)

- Conduct regulatory body or AHJ reviews and audits to assess adherence to established criteria

E. Quality monitoring and reporting

- Acceptance criteria definition and implementation

- Establish criteria for accepting work at various stages, such as mock-up inspection and testing,

initial inspection and testing, work-in-process inspection, punch list inspection, and final

inspection, testing, and commissioning. Integrate material verification at each stage to assess

if materials meet project specifications and quality standards. Apply escalation procedures to

address materials that do not meet established acceptance criteria. (Evaluate)

- Establish criteria for accepting work at various stages, such as mock-up inspection and testing,

- Reporting and analysis

- Design periodic reports and conduct statistical analyses to identify quality trends and assess

waste elimination. (Evaluate)

- Design periodic reports and conduct statistical analyses to identify quality trends and assess

- Meetings and participation

- Organize pre-inspection meetings that include quality meeting sample agenda items that address key topics, such as upcoming inspections, current quality metrics, recent findings, and open issues. (Evaluate)

- Lessons and improvements

- Incorporate lessons learned from previous projects into the quality monitoring and reporting

process. Document and communicate these lessons learned for future projects. Develop strategies

to assess and manage quality risks. Engage in root cause analyses and investigations to

understand underlying quality issues. Develop quality improvement programs based on identified

needs and insights. (Evaluate)

- Incorporate lessons learned from previous projects into the quality monitoring and reporting

- Levels of commissioning

- Understand and determine when to use the 5-level (factory acceptance test, component

verification, system construction, individual system and major equipment operation verification,

integrated system testing) and 8-level (preparation, design, pre-construction, construction,

commissioning of services, pre-handover, initial occupation, post-occupancy care) commissioning

frameworks. (Evaluate)

- Understand and determine when to use the 5-level (factory acceptance test, component

VI. Project Turnover and Closeout (11 Questions)

A. Documentation management

- Impact assessment and compliance

- Evaluate the potential impact arising from the demobilization of quality resources. Review and

assess inspection and test records related to safety critical equipment to determine if they are

compliant with required standards. Confirm how final documentation will be transferred to the

client (e.g., digital platforms, electronically, and hard copy). (Evaluate)

- Evaluate the potential impact arising from the demobilization of quality resources. Review and

- Required documentation

- Maintain comprehensive documentation throughout the project’s duration, including records of all

activities and changes. (Apply)

- Maintain comprehensive documentation throughout the project’s duration, including records of all

- Nonconforming work

- Ensure all work not conforming to contract specifications (i.e., punch list) is closed. (Evaluate)

- Quality deliverables verification

- Verify the completeness of all quality deliverables. (Evaluate)

- Final certification

- Facilitate the process for obtaining final certification, ensuring inclusion and maintenance of all

documentation related to each closeout milestone and stage (e.g., beneficial occupancy / use,

substantial completion, and final completion). Use the current version of Issued for Construction

(IFCs) documents. (Evaluate)

- Facilitate the process for obtaining final certification, ensuring inclusion and maintenance of all

- Final turnover and closeout documentation

- Audit the final turnover plan and related closeout documentation, including permit close out,

operations and maintenance manuals, as-built drawings, attic stock / spare parts records,

commissioning reports, and owner training materials. Confirm all quality inspection and test

records are reviewed and validated for fitness for use. (Evaluate)

- Audit the final turnover plan and related closeout documentation, including permit close out,

- Warranties

- Implement effective communication regarding the warranty program and documentation or

warranty work to all relevant stakeholders. (Evaluate)

- Implement effective communication regarding the warranty program and documentation or

VII. Operations and Maintenance (5 Questions)

A. Sustaining quality requirements

- Prepare quality objectives required for operations and maintenance (O&M) based on customer expectations. Understand how in-contract and warranty maintenance programs are used throughout the project lifecycle. Report future O&M inspections and testing strategies needed (e.g., building component health, risk-based) to the design team. (Apply)

B. Business continuity

- Provide inputs for facility shutdown plans, considering both planned (e.g., O&M-required) and unplanned events (e.g., weather or disaster-related incidents). Align the quality plan with the business continuity plan for operational resilience. Apply drills and simulations to test these plans. Monitor the quality-related impacts resulting from shutdowns. (Apply)

VIII. Quality Manager Skills (22 Questions)

A. ASQ Code of Ethics

- Demonstrate appropriate behaviors and actions that align with the ASQ Code of Ethics. (Analyze)

B. Stakeholder analysis and alignment

- Identify the perspectives, needs, and objectives of various internal and external stakeholders. Integrate collaboration and negotiation techniques to align the organization’s strategic objectives and stakeholder expectations. (Apply)

C. Team building

- Vision development

- Collaborate with stakeholders to adopt quality goals and a clear vision for a team or project.

(Apply)

- Collaborate with stakeholders to adopt quality goals and a clear vision for a team or project.

- Stages of team development

- Identify and distinguish between the stages of team development: forming, storming, norming,

performing, and adjourning. (Analyze)

- Identify and distinguish between the stages of team development: forming, storming, norming,

- Effective team dynamics and communication

- Employ various communication techniques (e.g., verbal, nonverbal, written, and visual) and

active listening. Collaborate with multiple groups (e.g., designers, project management, and craft

teams). Implement the Responsible, Accountable, Consulted, Informed (RACI) Matrix to clarify

roles and responsibilities and streamline decision-making processes. Understand decision-making

pitfalls (e.g., groupthink and power dynamics) to promote healthy team dynamics and achieve

project objectives. Resolve conflicts through established procedures. (Apply)

- Employ various communication techniques (e.g., verbal, nonverbal, written, and visual) and

D. Change management

- Organizational culture

- Define and explain the factors that shape an organization’s culture. (Apply)

- Change management strategies

- Analyze and provide input to various change management strategies to overcome organizational

roadblocks, adapt to global changes, assess the achieved change levels, and review outcomes

for effectiveness. (Analyze)

- Analyze and provide input to various change management strategies to overcome organizational

E. Cost of Quality (CoQ)

- Cost of Quality (CoQ) analysis

- Examine the methods and sources for collecting CoQ data. Interpret the CoQ data to derive

meaningful insights. Report and communicate findings from the CoQ data analysis. (Analyze)

- Examine the methods and sources for collecting CoQ data. Interpret the CoQ data to derive

- Improvement plans

- Incorporate CoQ as a foundation for improvement methodology, alongside Lean, Six Sigma

(e.g., DMAIC), and Deming’s System of Profound Knowledge (SoPK). Identify areas for

improvement from CoQ data analysis, and participate in the improvement plan to address these,

integrating the plan with existing business processes. Evaluate the effectiveness and applicability

of CoQ tools and methodologies. (Evaluate)

- Incorporate CoQ as a foundation for improvement methodology, alongside Lean, Six Sigma

- Organizational goals

- Assess how CoQ improvement efforts align with organizational goals. Monitor and measure

the progress made towards achieving organizational goals. Evaluate the steps taken to achieve

organizational goals based on CoQ improvements. (Evaluate)

- Assess how CoQ improvement efforts align with organizational goals. Monitor and measure

F. Customer satisfaction

- Customer feedback systems

- Apply feedback collection tools, such listening posts, focus groups, complaint logs, warranty

data, surveys, and interviews to capture positive and negative feedback. (Apply)

- Apply feedback collection tools, such listening posts, focus groups, complaint logs, warranty

- Customer value analysis

- Analyze a customer value analysis to determine the financial impact of customer retention and the

potential consequences of customer attrition. (Analyze)

- Analyze a customer value analysis to determine the financial impact of customer retention and the

- Customer experience enhancement

- Evaluate corrective strategies and proactive methods to enhance customer satisfaction, loyalty,

and retention. (Evaluate)

- Evaluate corrective strategies and proactive methods to enhance customer satisfaction, loyalty,

G. Quality management tools

- Quality tools

- Select the appropriate tool and evaluate the output from the seven classic quality tools (Pareto

charts, cause and effect diagrams, flowcharts, control charts, check sheets, scatter diagrams, and

histograms) as preventive measures, analyze root causes, and problem solve. (Evaluate)

- Select the appropriate tool and evaluate the output from the seven classic quality tools (Pareto

- Learning and best practices analysis

- Incorporate after-action reviews, and root cause analysis (RCA) meetings to critically assess

project outcomes and identify lessons learned from all phases of the project, identifying both

successes and areas for improvement. Analyze the critical success factors that led to best

practices being implemented within the project. Use key performance indicators (KPIs) to

systematically track and assess the impact of implemented improvements and evaluate strategies

to reinforce and replicate these improvements across future projects. (Evaluate)

- Incorporate after-action reviews, and root cause analysis (RCA) meetings to critically assess

- Knowledge management analysis

- Document the strategies and outcomes of knowledge management throughout the project. (Apply)

Certified Construction Quality Manager (CCQM): FAQs

Policies and Procedures

Below are some of the exam-related policies:

Identification Policy

You must present one valid, government-issued photo ID with a signature, such as a driver’s license or passport. The name on your ID must exactly match the name on your application. During your time at the test center, all personal items will be stored in a temporary Prometric locker. You may keep only your ID and locker key with you.

References/Open Book Policy

Prometric will supply scratch paper and pencils. All ASQ exams are open book, and reference materials (including notes) must be securely bound and remain so throughout the exam. “Bound” refers to materials that are permanently bound by stitching or glue, or securely fastened in a cover by fasteners like ring binders, spiral binders, plastic snap binders, brads, or screw posts. Hand-stapled documents that are not securely fastened are not permitted. The Test Center Administrator (TCA) will review all reference materials before you enter the exam room. “Post-It” notes may be used as tabs, but they must be attached before entering the test center.

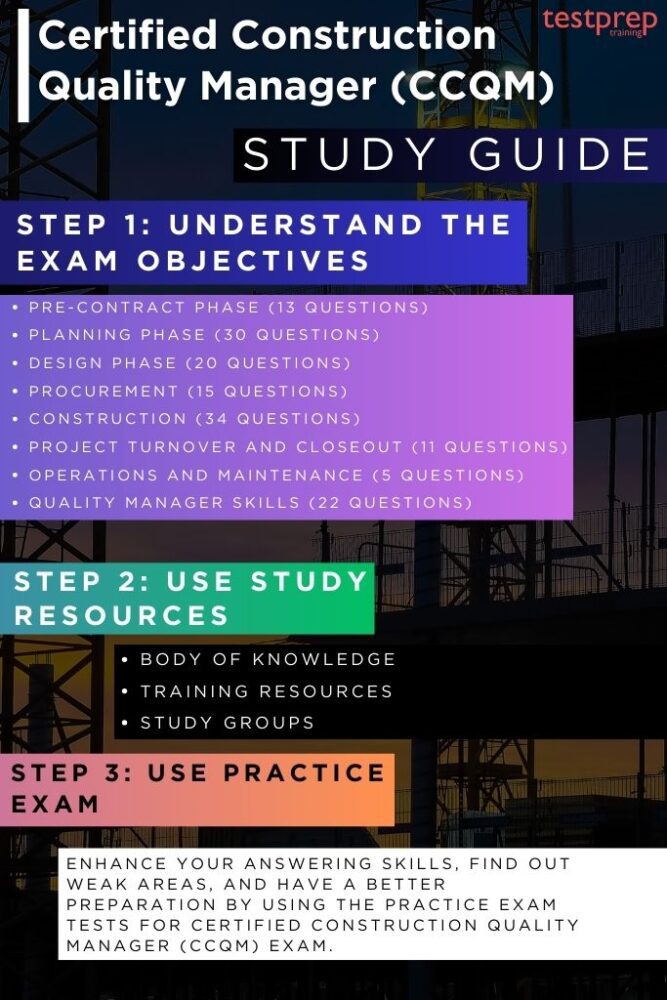

Certified Construction Quality Manager (CCQM) Exam Study Guide

1. Understand the Exam Body of Knowledge

To prepare for the Certified Construction Quality Manager (CCQM) exam, it’s essential to understand the Body of Knowledge (BoK) thoroughly. The BoK outlines the core areas and specific topics the exam will cover, detailing the knowledge and skills expected of construction quality management professionals. Each topic includes subtext explanations and a cognitive level indicator, providing candidates with insight into the depth and complexity of questions they might encounter. Reviewing the BoK not only clarifies the exam’s content but also guides candidates on how to prioritize study areas and understand the practical application of concepts, enhancing both preparation and confidence in tackling the CCQM exam.

2. Utilize ASQ Study Resources

Using ASQ study resources can be highly beneficial when preparing for the Certified Construction Quality Manager (CCQM) exam. ASQ provides various materials designed to help candidates grasp key concepts and competencies outlined in the exam’s Body of Knowledge. Resources include detailed study guides, sample questions, and recommended reading that align with the exam’s cognitive levels, ensuring a comprehensive understanding of topics like quality control, project management, risk assessment, and more. Leveraging ASQ resources can clarify complex principles, enhance test readiness, and improve confidence for successfully achieving CCQM certification.

3. Join Study Groups

Joining study groups for the Certified Construction Quality Manager (CCQM) exam can significantly enhance your preparation experience. Engaging with fellow candidates allows for the sharing of knowledge, resources, and different perspectives on challenging topics within the Body of Knowledge. Study groups provide opportunities for collaborative learning, where members can discuss complex concepts, quiz each other, and clarify doubts. This collective approach fosters motivation and accountability, helping you stay on track with your study schedule. Whether online or in-person, participating in a study group can enrich your understanding of the material and increase your confidence heading into the exam.

4. Take Practice Tests

Utilizing practice tests is an effective strategy for preparing for the Certified Construction Quality Manager (CCQM) exam. These tests simulate the actual exam environment and provide insight into the types of questions you may encounter, helping you familiarize yourself with the format and timing. By regularly taking practice tests, you can identify your strengths and weaknesses, allowing you to focus your study efforts on areas that require improvement.

Additionally, reviewing the results of these tests can enhance your understanding of the exam’s Body of Knowledge and reinforce key concepts. Overall, incorporating practice tests into your study plan can boost your confidence and improve your chances of success on the CCQM exam.