Six Sigma Green Belt (SSGB) is a professional certification that recognizes an individual’s knowledge and skills in applying the Six Sigma methodology to improve business processes. The SSGB certification is awarded to individuals who have completed training in Six Sigma methodology and demonstrated their proficiency by passing an SSGB certification exam.

A Six Sigma Green Belt typically works as a team member or project leader in a Six Sigma project. They are responsible for data collection and analysis, identifying the root cause of problems, implementing process improvements, and monitoring the process to ensure sustained improvement. The SSGB certification indicates that the individual has the knowledge and skills to support Six Sigma projects and contribute to process improvement initiatives within an organization.

Glossary: Six Sigma Green Belt (SSGB)

Here are some key terms and concepts related to Six Sigma Green Belt (SSGB):

- Six Sigma: A methodology for quality improvement that uses data-driven approaches to identify and remove defects or variations in a process.

- Green Belt: A level of Six Sigma certification that demonstrates a basic understanding of Six Sigma concepts and tools.

- DMAIC: A problem-solving approach employed in Six Sigma, abbreviated as DMAIC, which stands for Define, Measure, Analyze, Improve, and Control.

- Process mapping: A tool used for visually representing the steps involved in a process.

- Root cause analysis: A problem-solving technique used to identify the underlying cause of a problem.

- Statistical process control (SPC): A tool used to monitor and control a process over time, using statistical methods to analyze process data.

- Control charts: A graphical tool used in SPC to display process data over time and identify trends or patterns.

- Pareto chart: A graphical tool used to identify the most significant factors contributing to a problem.

- Lean principles: A set of principles and tools used to optimize processes and reduce waste.

- Value stream mapping: A tool used for visualizing the flow of materials and information in a process and discovering areas of waste or inefficiency.

- Design of experiments (DOE): A statistical technique used to systematically test and optimize the factors that influence a process.

- Kaizen: A Japanese term meaning “continuous improvement,” which refers to a philosophy of ongoing process improvement.

- FMEA: Failure Mode and Effects Analysis is a structured approach to identify and mitigate potential risks in a process.

- MSA: Measurement System Analysis is a method for evaluating the accuracy and consistency of measurement systems used in the process.

Tips and tricks: Six Sigma Green Belt (SSGB)

Here are some tips for creating a study guide for Six Sigma Green Belt (SSGB) certification:

- Review the certification body’s exam content outline: This will provide an overview of the topics covered in the exam and help you create a study plan.

- Identify your strengths and weaknesses: Take a practice exam or review materials for discovering the areas where you need more practice.

- Create a study schedule: Set aside regular study time and create a schedule that allows you to cover all the topics before the exam date.

- Collect study materials: Gather textbooks, online resources, practice exams, and other materials to support your study plan.

- Use flashcards: Create flashcards to help memorize key terms and concepts.

- Take practice exams: Practice exams can help you discover areas that require more study and create a level of confidence for the real exam.

- Join study groups: Join or create a study group with other candidates to discuss topics and share study materials.

- Utilize online resources: There are many online resources, such as forums and study guides, available to help you prepare for the exam.

- Practice problem-solving: Practice solving problems using the DMAIC methodology and other Six Sigma tools.

- Stay motivated and focused: Keep a positive attitude and stay motivated throughout your study process. Set achievable goals and celebrate your progress along the way.

Six Sigma Green Belt (SSGB) Exam Resources

The American Society for Quality (ASQ) offers certification exams for Six Sigma Green Belt (SSGB) professionals. Here are some exam resources provided by ASQ:

- SSGB Body of Knowledge: The SSGB Body of Knowledge outlines the topics covered in the SSGB certification exam. It includes topics such as Six Sigma methodology, statistical tools and techniques, project management, and process improvement.

- SSGB Exam Preparation Materials: ASQ offers several exam preparation materials, including study guides, practice exams, and webinars. These materials can help individuals prepare for the SSGB certification exam.

- ASQ Certification Handbook: The ASQ Certification Handbook provides detailed information about the SSGB certification exam, including eligibility requirements, exam content, and exam registration.

- SSGB Practice Exam: ASQ offers a practice exam for the SSGB certification exam. The practice exam provides individuals with an opportunity to test their knowledge and identify areas where they may need to focus their study efforts.

- SSGB Exam Reference Materials: During the SSGB certification exam, individuals are allow to use reference materials. ASQ provides a list of approve reference materials that can be used during the exam.

- SSGB Exam Retake Policy: ASQ offers a retake option for the SSGB certification exam, allowing individuals who do not pass the exam on their initial try to retake it within a specified timeframe.

In summary, ASQ provides several resources for individuals preparing for the Six Sigma Green Belt (SSGB) certification exam, including the SSGB Body of Knowledge, exam preparation materials, the ASQ Certification Handbook, a practice exam, approved reference materials, and a retake policy. These resources can help individuals prepare for and successfully pass the SSGB certification exam.

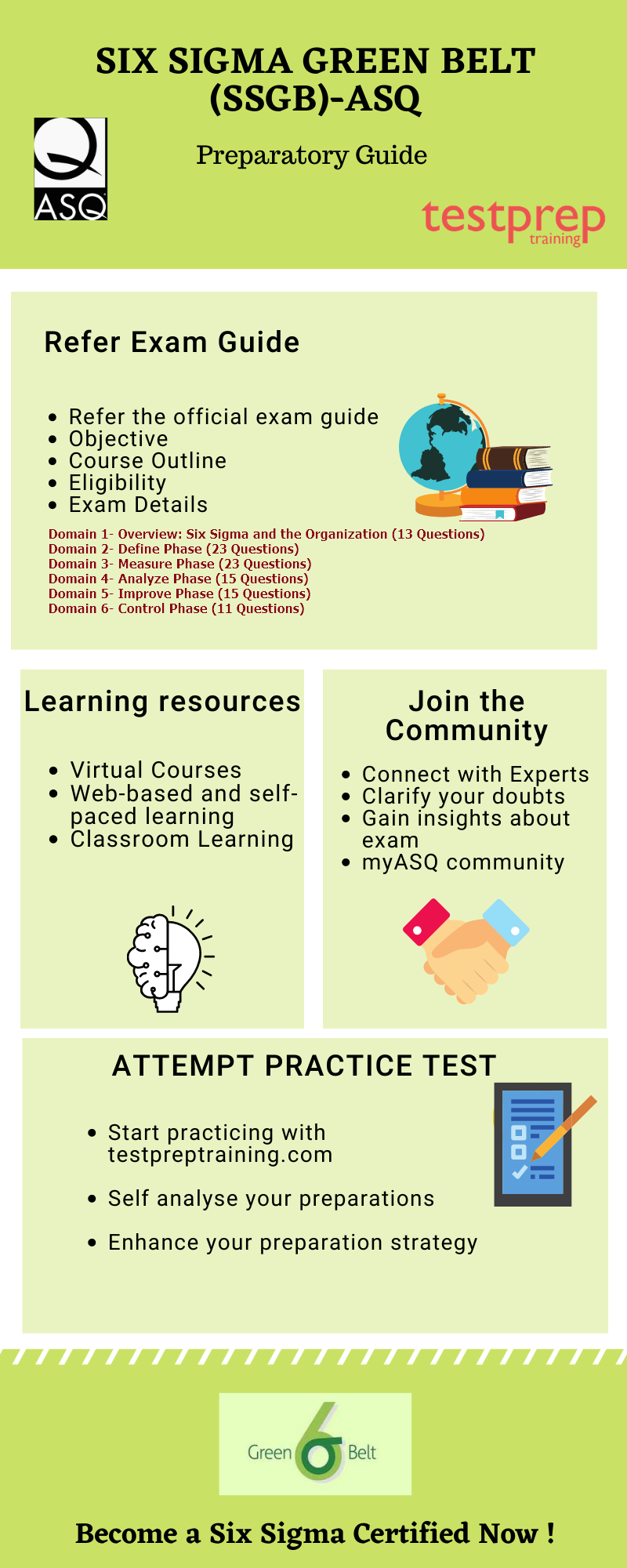

Preparatory Guide for Six Sigma Green Belt (SSGB) Exam

It is extremely important to have all the exam preparation resources with the study guide to excel in the exam. This may seem easy but having complete exam details, and good learning resources will be the only saviour to pass the exam successfully. Let’s discuss them with our step-by-step Study Guide.

Step 1 – Refer the Exam Guide

The most crucial aspect of your preparation is thoroughly reviewing each exam objective. Therefore, ensure you visit the official exam website for accurate and reliable information. This website is the most authoritative source for all exam-related details. Once you’ve familiarized yourself with the fundamental exam information, it’s time to delve into the exam guide. Revisit all the concepts covered in this examination, and be sure to gain a comprehensive understanding of the domains, as they serve as the cornerstone of the exam. The exam encompasses the following areas:

I. Overview: Six Sigma and the Organization (11 Questions)

A. Six Sigma and Organizational Goals

1. Value of Six Sigma

- Recognizes why companies utilize Six Sigma

- how they apply their philosophy and aims

- how Six Sigma evolved from quality leaders like Juran, Deming, Shewhart, and Ishikawa. (Understand).

(ASQ Reference: Project Selection Index, The Evolution of Six Sigma)

2. Organizational goals and Six Sigma projects

- Describe how process inputs, outputs, and feedback at all levels may impact the organization as a whole, and identify the links and supports that need to be developed between a selected Six Sigma project and the organization’s goals. (Understand)

(ASQ Reference: Six Sigma)

3. Organizational drivers and metrics

- Recognize major business motivations for all sorts of firms (profit, market share, customer happiness, efficiency, and product differentiation). Learn how essential metrics and scorecards are created, as well as how they affect the whole company. (Understand) (ASQ Reference: Performance metrics)

B. Lean Principles in the Organization

1. Lean concepts

- Define and describe lean concepts such as the theory of constraints, value chain, flow, and perfection. (Apply) (ASQ Reference: Introduction To Lean Principles)

2. Value stream mappings

- Use value stream mapping to identify value-added processes and steps or processes that produce waste, including excess inventory, unused space, test inspection, rework, transportation, and storage. (Understand). (ASQ Reference: Value stream mapping (VSM))

C. Design for Six Sigma (DFSS) Methodologies

1. Road maps for DfSS

- Distinguish between DMADV (define, measure, analyze, design, verify) and IDOV (identify, design, optimize, verify), and recognize how they align with DMAIC. Describe how these methodologies are used for improving the end product or process during the design (DfSS) phase. (Understand) (ASQ Reference: Design For Six Sigma (DFSS))

2. Basic failure mode and effects analysis (FMEA)

- Use FMEA to evaluate a process or product and determine what might cause it to fail and the effects that failure could have. Identify and use scale criteria, calculate the risk priority number (RPN), and analyze the results. (Analyze) (ASQ Reference: FAILURE MODE AND EFFECTS ANALYSIS (FMEA))

3. Design FMEA and process FMEA

- Define and distinguish between these two uses of FMEA. (Apply) (ASQ Reference: FMEA)

4. Process inputs and outputs

- Identify process input and output variables and evaluate their relationships using the supplier, input, process, output, customer (SIPOC) model. (Analyze) (ASQ Reference: More Than Inputs and Outputs)

5. Owners and stakeholders

- Identify the process owners and other stakeholders in a project. (Apply) (ASQ Reference: STAKEHOLDERS)

II. Define Phase (20 Questions)

A. Project Identification

1. Project selection

- describes the project selection process and what factors should be considered in deciding whether to use the Six Sigma DMAIC methodology or another problem-solving process. (Understand). (ASQ Reference: THE DEFINE, MEASURE, ANALYZE, IMPROVE, CONTROL (DMAIC) PROCESS)

2. Process elements

- Define and describe process components and boundaries. Recognize how processes across various functional areas and the challenges that result in process improvement efforts. (Analyze) (ASQ Reference: QUALITY PLAN)

3. Benchmarking

- Understand various types of benchmarking, including competitive, collaborative, and best practices. (Understand) (ASQ Reference: WHAT IS BENCHMARKING?)

4. Process inputs and outputs

- Identify process input and output variables and evaluate their relationships using the supplier, input, process, output, customer (SIPOC) model. (Analyze) (ASQ Reference: SIPOC+CM DIAGRAM)

5. Owners and stakeholders

- Identify the process owners and other stakeholders in a project. (Apply) (ASQ Reference: IDENTIFYING STAKEHOLDERS)

B. Voice of the Customer (VoC)

1. Customer identification

- Identify the internal and external customers of a project, and what effect the project will have on them. (Apply) (ASQ Reference: WHAT IS CUSTOMER SATISFACTION?)

2. Customer data

- Collect feedback from customers using surveys, focus groups, interviews, and various forms of observation. Identify the key elements that make these tools effective. Review data collection questions to eliminate vagueness, ambiguity, and any unintended bias. (Apply) (ASQ Reference: Airport Service Quality (ASQ))

3. Customer requirements

- Use quality function deployment (QFD) to translate customer requirements statements into product features, performance measures, or opportunities for improvement. Use weighting methods as needed to amplify the importance and urgency of different kinds of input; telephone call vs. survey response; product complaint vs. expedited service request. (Apply) (ASQ Reference: WHAT IS QUALITY FUNCTION DEPLOYMENT (QFD)?)

C. Project Management Basics

1. Project charter

- Define and describe elements of a project charter and develop a problem statement that includes baseline data or current status to be improved and the project’s goals. (Apply) (ASQ Reference: Project Charter Template)

2. Project scope

- Help define the scope of the project using process maps, Pareto charts, and other quality tools. (Apply) (ASQ Reference: Project Overview)

3. Project metrics

- Help develop primary metrics (reduce defect levels by x-amount) and consequential metrics (the negative effects that making the planned improvement might cause). (Apply) (ASQ Reference: SELECTING PERFORMANCE MEASURES & METRICS)

4. Project planning tools

- Use Gantt charts, critical path method (CPM), and program evaluation and review technique (PERT) charts to plan projects and monitor their progress. (Apply) (ASQ Reference: PROJECT PLANNING AND IMPLEMENTATION TOOLS)

5. Project documentation

- Describe the types of data and input needed to document a project. Identify and help develop appropriate presentation tools (storyboards, spreadsheet summary of results) for phase reviews and management updates. (Apply)

6. Project risk analysis

- Describe the elements of a project risk analysis, including feasibility, potential impact, and risk priority number (RPN). Identify the potential effect risk can have on project goals and schedule, resources (materials and personnel), costs and other financial measures, and stakeholders. (Understand)

7. Project closure

- Review with team members and sponsors the project objectives achieved in relation to the charter and ensure that documentation is completed and stored appropriately. Identify lessons learned and inform other parts of the organization about opportunities for improvement(apply). (ASQ Reference: Project Overview)

D. Management and Planning Tools

- Define, select, and apply these tools: 1) affinity diagrams, 2) interrelationship digraphs, 3) tree diagrams, 4) prioritization matrices, 5) matrix diagrams, 6) process decision program charts (PDPC), and 7) activity network diagrams. (Apply)

E. Business Results for Projects

1. Process performance

- Calculate process performance metrics such as defects per unit (DPU), rolled throughput yield (RTY), cost of poor quality (CoPQ), defects per million opportunities (DPMO), sigma levels, and process capability indices. Track process performance measures to drive project decisions. (Analyze) (ASQ Reference: WHAT IS PROCESS CAPABILITY?)

2. Communication

- Define and describe communication techniques used in organizations: top-down, bottom-up, and horizontal.(apply) ASQ Parent Communication Tools)

F. Team Dynamics and Performance

1. Team stages and dynamics

- Define and describe the stages of team evolution, including forming, storming, norming, performing, adjourning, and recognition. Identify and help resolve negative dynamics such as overbearing, dominant, or reluctant participants, the unquestioned acceptance of opinions as facts, groupthink, feuding, floundering, the rush to accomplishment, attribution, discounts, digressions, and tangents. (understand). (ASQ Reference: Team Basics)

2. Team roles and responsibilities

- Describe and define the roles and responsibilities of participants on Six Sigma and other teams, including Black Belt, Master Black Belt, Green Belt, champion, executive, coach, facilitator, team member, sponsor, and process owner. (Apply)

3. Team tools

- Define and apply team tools such as brainstorming, nominal group technique, and multi voting. (Apply) (ASQ Reference: Team Tools)

4. Team Communication

- Identify and use appropriate communication methods (both within the team and from the team to various stakeholders) to report progress, conduct reviews, and support the overall success of the project. (Apply)

III. Measure Phase (20 Questions)

A. Process Analysis and Documentation

- Develop process maps and review written procedures, work instructions, and flowcharts to identify any gaps or areas of the process that are misaligned. (Create)B. Probability and Statistics (ASQ Reference: PROCESS ANALYSIS TOOLS)

B. Probability and Statistics

1. Basic probability concepts

- Identify and use basic probability concepts: independent events, mutually exclusive events, multiplication rules, permutations, and combinations. (Apply) (ASQ Reference: Basic Statistics)

- Central limit theorem Define the central limit theorem and describe its significance in relation to confidence intervals, hypothesis testing, and control charts. (Understand)

C. Statistical Distributions

- Define and describe various distributions as they apply to statistical process control and probability: normal, binomial, Poisson, chi square, Student’s t, and F. (Understand) (ASQ Reference: The Probability Handbook)

D. Collecting and Summarizing Data

1. Types of data and measurement scales

- Identify and classify continuous (variables) and discrete (attributes) data. Describe and define the nominal, ordinal, interval, and ratio measurement scales. (Analyze) (ASQ Reference: WHAT IS ATTRIBUTE DATA AND VARIABLE DATA?)

2. Sampling and data collection methods

- Define and apply various sampling methods (random and stratified) and data collection methods (check sheets and data coding). (Apply) (ASQ Reference: WHAT IS A DATA COLLECTION SURVEY?)

3. Descriptive statistics

- Define, calculate, and interpret measures of dispersion and central tendency. Develop and interpret frequency distributions and cumulative frequency distributions. (Evaluate) (ASQ Reference: STATISTICAL METHODS IN QUALITY IMPROVEMENT)

4. Graphical methods

- Construct and interpret diagrams and charts that are designed to communicate numerical analysis efficiently, including scatter diagrams, normal probability plots, histograms, stem-and-leaf plots, box-and-whisker plots. (Create) (ASQ Reference: Statistics)

E. Measurement System Analysis (MSA)

- Calculate, analyze, and interpret measurement system capability using gauge repeatability and reproducibility (GR&R) studies, measurement correlation, bias, linearity, percent agreement, and precision/tolerance (P/T). (Evaluate) (ASQ Reference: Measurement System Analysis)

F. Process and Performance Capability

1. Process performance vs. process specifications

- Define and distinguish between natural process limits and specification limits, and calculate process performance metrics. (Evaluate) (ASQ Reference: Process Capability)

2. Process capability and studies

- Define, describe, and conduct process capability studies, including identifying characteristics, specifications, and tolerances, and verifying stability and normality. (Evaluate) (ASQ Reference: WHAT IS PROCESS CAPABILITY?)

3. Process capability (Cp, Cpk) and process performance (Pp, Ppk) indices

- describe the relationship between these types of indices. Define, select, and calculate process capability and process performance. Describe when Cpm measures can be used. Calculate the sigma level of a process. (Evaluate) (ASQ Reference: Process Capability Indices)

4. Short-term vs. long-term capability and sigma shift

- Describe the assumptions and conventions that are appropriate to use when only short-term data are used. Identify and calculate the sigma shift that occurs when long- and short-term data are compared. (Evaluate)

IV. Analyze Phase (18 Questions)

A. Exploratory Data Analysis

1. Multi-vari studies

- Select appropriate sampling plans to create multi-vari study charts and interpret the results for positional, cyclical, and temporal variation. (Create) (ASQ Reference: Six Sigma, Measurement Systems, and the Hidden Factory)

2. Correlation and linear regression

- Describe the difference between correlation and causation. Calculate the correlation coefficient and linear regression and interpret the results in terms of statistical significance (p-value). Use regression models for estimation and prediction. (Evaluate) (ASQ Reference: Correlation And Regression)

B. Hypothesis Testing

1. Basics

- Distinguish between statistical and practical significance. Determine appropriate sample sizes and develop tests for a significance level, power, and type I and type II errors. (Apply) (ASQ Reference: BASIC QUALITY)

2. Tests for means, variances, and proportions

- Conduct hypothesis tests to compare means, variances, and proportions (paired-comparison t-test, F-test, analysis of variance [ANOVA], chi-square), and interpret the results. (Analyze)

V. Improve Phase (16 Questions)

A. Design of Experiments (DoE)

1. Basic terms

- Define and describe terms such as independent and dependent variables, factors and levels, responses, treatments, errors, repetition, blocks, randomization, effects, and replication. (Understand) (ASQ Reference: WHAT IS DESIGN OF EXPERIMENTS (DOE)?)

2. DoE graphs and plots

- Interpret main effects analysis and interaction plots. (Apply) (ASQ Reference: Design of experiments (DOE))

B. Root Cause Analysis

- Use cause and effect diagrams, relational matrices, and other problem-solving tools to identify the true cause of a problem. (Analyze) (ASQ Reference: Root Cause Analysis)

C. Lean Tools

1. Waste elimination

- Select and apply tools and techniques for eliminating or preventing waste, including pull systems, kanban, 5S, standard work, and poka-yoke. (Apply) (ASQ Reference: WHAT IS LEAN?)

2. Cycle-time reduction

- Use various techniques to reduce cycle time (continuous flow, setup reduction). (Analyze) (ASQ Reference: Cycle-Time Redesign)

3. Kaizen and kaizen blitz

- Define and distinguish between these two methods and apply them in various situations. (Apply) (ASQ Reference: Kaizen Blitz Road Map)

VI. Control Phase (15 Questions)

A. Statistical Process Control (SPC)

1. SPC Basics

- Describe the theory and objectives of SPC, including measuring and monitoring process performance for both continuous and discrete data. Define and distinguish between common and special cause variation and how these conditions can be deduced from control chart analysis. (Analyze) (ASQ Reference: SPC Basics Online)

2. Rational subgrouping

- Define and describe how rational subgrouping is used. (Understand) 3. Control charts Identify, select, construct, and use control charts: X-R, X-s, individual, and moving range (ImR or XmR), median, p, np, c, and u. (Apply)

B. Control Plan

- Assist in developing and implementing a control plan to document and monitor the process and maintain the improvements. (Apply)

C. Lean Tools for Process Control

1. Total productive maintenance (TPM)

- Define the elements of TPM and describe how it can be used to control the improved process. (Understand) (ASQ Reference: Total Productive Maintenance)

2. Visual factory

- Define the elements of a visual factory and describe how it can be used to control the improved process. (Understand) (ASQ Reference: Visual Management)

Step 2 – Explore Learning Resources

Passing the exam can be easy if you have access to the right set of resources. Make sure the content is precise and reliable enough. The resources that you’ll pick will determine how well you prepare and pass the exam. Hence, you need to be very careful while choosing the preparatory resources. Lets look at some of the available resources you must include in your preparation journey.

Use Exam Simulator

Provides sample exam questions based on the Certified ASQ – Six Sigma Green Belt. You can use the question sets in two different modes — Exam simulation or review mode.

Learn from CSSBB Books

ASQ also provides a handbook to ease your exam preparation process and also to help you in appearing for the open book exam. This will help you prepare well in the examination. Along with this book, ASQ also provides free sample questions and answers to give you an insight into the examination.

- ASQ CSSGB HandBook: Can be use in your open book exam.

Enrol for Classroom

The participants of ASQ – Six Sigma Black Belt classroom are already practising Green Belts who want to refresh their knowledge and skills, they will need a hand-held, electronic calculator (such as TI-30Xa) for the course. The format of this course is an instructor-led traditional classroom and includes classroom-based instruction involving the highest level of instructor/student interaction. The classroom-style training is provided in two formats. See the public and on-site.

Go for Web-based and self-paced learning

This course is web-based and self-paced. It includes internet-based, self-paced training modules, which may involve combinations of text, visuals, audio, interactive simulations, and quizzes. This course does not teach but rather reviews concepts in the handbook. These web-based courses require a computer and Internet access.

Choose Virtual Courses

These Virtual courses are for Green Belts who are backing Six Sigma projects or aspiring to attain their ASQ Six Sigma Green Belt certification. It incorporates real-world examples and hands-on activities to assist you in getting ready for the ASQ SSGB certification exam. The course covers the concepts outlined in the SSGB Body of Knowledge (BoK). ASQ also provides this training course in a traditional instructor-led classroom format. Additionally, on-site training is an option for groups of five or more, offering convenience, cost-effectiveness, and the potential for customizing the course to meet your organization’s specific needs when you have our top-tier instructors on-site.

Step 3 – Join Online Communities

myASQ communities are utilized for networking, sharing content, and peer-to-peer learning. Some of these communities are gate and are determined by your member profile. Membership in technical and geographic communities are include or can be added to an ASQ membership. When more people get involved, it becomes much easier to find answers to problems. Different points of view make discussions more interesting and lively. These conversations help us understand things better, and they give shy people a chance to share their ideas, even if they usually stay quiet. Online forums are great for building a community where we can learn from others and understand their views better.

Step 4 – Prepare with Practice Tests

To get better at taking the real exam, you should do practice tests. The more you practice, the less difficult the real exam will feel. Doing these practice tests will teach you about how the real exam works. They are made to figure out what you know and what you don’t know. This helps you feel more at ease during the real exam and allows you to plan how you study. The results from practice tests can show if you are as knowledgeable as you thought or if you need to study more. Lets Start Practising Now!